MADE IN FINLAND – EXTREME CONDITIONS? BRING IT ON!

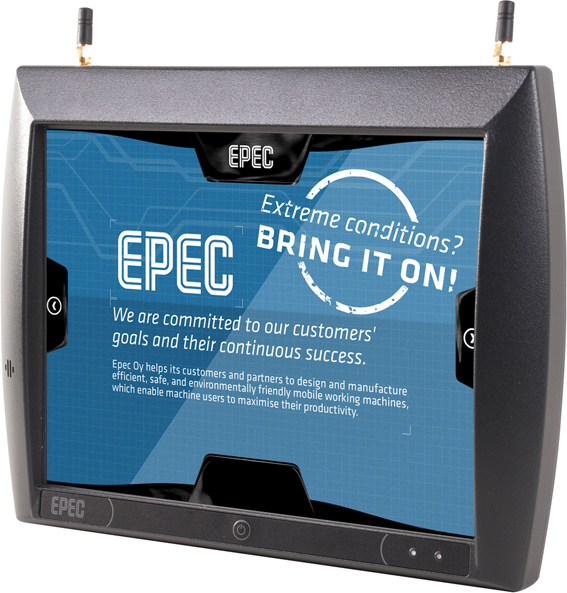

Simple interaction and usage of a machine are key elements in any machine application. Freely programmable graphical user interface provides an opportunity to maximize machine usability and efficiency. With a 5.7” TFT display size, the 2040 Color Display is an ideal solution for heavy duty applications like mining machines, excavators, forest machines, wheel loaders etc. Fully enclosed aluminum housing provides water and dust proof operation according to IP66. The temperature ranges from -20 ° C to +60 ° C.

The 2040 Color Display is equipped with two CAN bus interfaces, a hardware configurable serial interface (RS232/422/48S), an Ethernet and USB interface via AMPSEAL connectors, thus allowing the display to be connected as an integral part of the embedded machine control system. The display has five integrated push buttons for operating, and, when using C programmed applications, it is also possible to connect an external user wheel or a standard USB mouse to further enhance the user experience.

Ethernet can be used to connect the machine to upper level information systems, such as databases for monitoring production, enterprise resource planning (ERP), etc.

The 2040 Color Display is fully programmable display unit and CoDeSys Visualization makes programming very easy. This graphical windows tool can be used to design display gauge meters, icons, buttons, texts, etc. Typically the display application may have several dozens of windows, and is used to adjust and store system parameters, application back up copies, system event logs etc. The display supports also feature where two separate displays are installed in the same machine. For C-programmable displays licenses for Remote access library and Modbus/TCP Slave communication are available as an option.

EPC-i10 is designed for use in extreme conditions where vibration, wide temperature changes and moisture are encountered every day. They were the criteria for design and also for selection of components used. Pre-heater for low temperatures, robust aluminum housing and a toughened glass TFT screen with LED backlight together with the dust and splash protection (IP54) form base for reliable operation.

The unit has some digital inputs and outputs, rich set of communication interfaces such as 2x CAN, 2x Video Input, GPS, GPRS/EDGE and the standard interfaces known from personal computers. As an option WLAN and bluetooth are also available. Special feature with modem used is that it has two SIM card slots.

Standard operating system allows usage of commercial software. Machine specific software can be written for instance with CoDeSys SoftPLC or Epec´s own .NET based software platform. EPC-i10 offers excellent platform for creating reliable, efficient and user-friendly HMI for the control system.

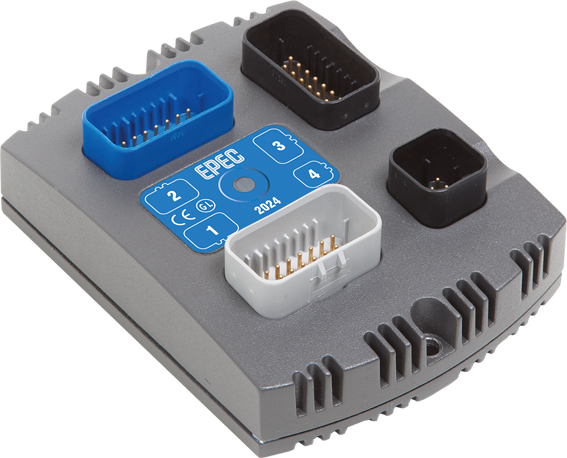

Epec 2024 Universal Control Unit is a compact multifunction controller and it has an optimized number of both input and output pins to be used for numerous roles in the control system.

The total number of I/O pins is 52, including digital inputs and outputs, analog inputs, pulse inputs, proportional (PWM) outputs, and current feedback inputs.

Epec 2038 Mini Control Unit is the smallest control unit with 20 I/O pins for embedded control systems. The control unit is used independently in smaller machines or with other control units in larger systems. With the help of the 2038 Mini Control Unit it is possible to even further deepen the distribution of intelligence around the machine by locating the control unit next to connectable sensors, actuators, and other devices spread around the machine.

There are two variations of this control unit. One variation of this control unit has two CAN bus interfaces. The other variation has CAN bus and RS232 serial interfaces.

Epec 5000 product family futher expands Epec´s product portfolio. It´s first launch, Epec 5050 Control Unit is an extremely compact, powerful and robust multifunction controller. 32-bit processor and increased calculating power makes this unit hard to beat. New Epec 5000 product platform is fully compatible to the existing Epec product portfolio.

Epec 5050 control unit has the same tested and proven heavy-duty design as all Epec control units, all specially designed for mobile machines operating in very hard environmental conditions.

The robust, light and leak proof aluminum/plastic cover has been widely tested against different chemicals. Also, the unique shape of the casing works to protect the electronics inside against mechanical wear. Three point anchorage confirms firm mounting also on irregular sufraces.

Open and compatible

Epec control system products are based on PLCopen and CANopen®, which make them easily scalable to meet requirements for both small and large machines. Units have open I/O and communication interface, thus making it possible to connect sensors, actuators, joysticks, and other devices from other manufacturers to optimize the whole machine environment, both technically and ergonomically.

Robust multifunction controller

Compact Epec 5050 Control Unit has an optimized number of both input and output pins to be used for numerous roles in the control system. The total number of I/O pins is 65, including digital inputs and outputs, analog inputs, pulse inputs and proportional (PWM) outputs. All I/O pins are equipped with a short-circuit protection. Pulse inputs have threshold voltage selection.

Totally new design of the robust unit carries plenty of new features such as signal LED, floating point calculation and high side current measurement in PWM-outputs. Program downloading is now possible through both CAN bus and Ethernet. Another new feature is also internal error logging, which makes it possible to save e.g. overvoltage and overtemperature alarms as well as program customized log applications. One CAN is equipped with double pins, which makes cabling easier since there is no need for branches in the wire harness.

Epec CANopen® Slave Units product family consists of Epec 2033 Power Switch Unit and 38 CANopen® Slave M1. These reliable, robust and easy-to-use generic I/O slaves answer the ever increasing demand to integrate all machine functions with intelligent machine control and they can be used as CANopen® slave with DS401 profile. The slave units operate in a wide temperature range and are also very easy to mount due to their compact size. The Epec CANopen® slave units´total robustness and snap-in AMP connectors also give you plenty of scope for a flexible mounting.

Epec 2033 Power Switch Unit

Epec 2033 Power Switch Unit can be used to control high currents up to 40 A. By using the 2033 Unit instead of typically used high current relays, one is able to save valuable space, reduce mechanical failure possibilities, and itegrate all the controlling seamlessly with the machine control system. Everything happens easily and automatically controlled by the total control system. The 2033 Unit offers maximum continuous current up to 40 A, which is much more than typical units can offer.

Epec 38 CANopen® Slave M1

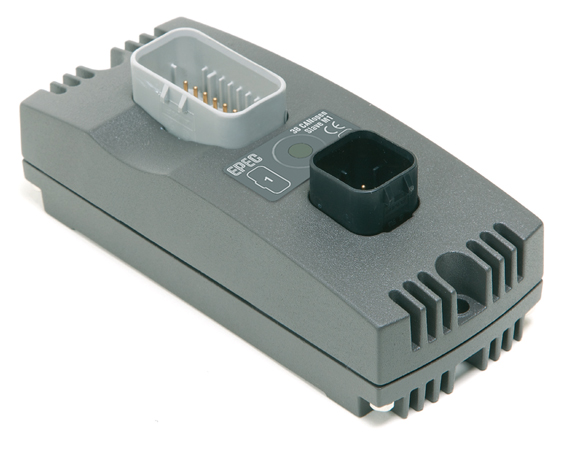

Epec 38 CANopen® Slave M1 is a versatile control unit for a CAN based control system with a very small footprint and highly flexible configuration capabilities. The 38 Slave Unit is one of the smallest control unit available for embedded control systems, yet offers a considerable amount (20 pc.) of controllable I/Os. The 38 Slave Units are easy blocks for creating embedded control systems or to expand the I/Os of an active control unit.